产品中心

PRODUCTSContact Us

Guangzhou Light Industry Machinery Equipment Co., Ltd.

Tel:86 20-3436 7336

Sale:86 20-3436 7336 turn 801 or 13925122993

Fax:86 20-3436 7283

400 free service hotline:400 1683 993

Factory address: Foshan in the South industrial zone two Road No. 3

Headquarters address: Haizhuqu District Industrial Avenue, South Garden, fifty-five, No. three, Guangzhou

公司简介

Your location: > PRODUCTS > Foam cleaning system > Automatic cleaning systemPrinciple of the scope of application

The method of foaming is to add the foam mother liquor in proportion to the high pressure water. The solution is thoroughly mixed in the mixer and then allowed to foam. The foam is then sprayed through the outlet hose and spray gun. Of the surface, the cleaning fluid and dirt to maintain adequate contact time, and then rinse with high pressure water can be easily peeled in the state of the dirt is easy to remove. Automatic cleaning and filling equipment for aseptic filling equipment in the beer and beverage industry Manual cleaning of the surrounding environment can also be used for automatic cleaning of major equipment such as food and pharmaceutical industries and manual cleaning of production environment.

System components and features:

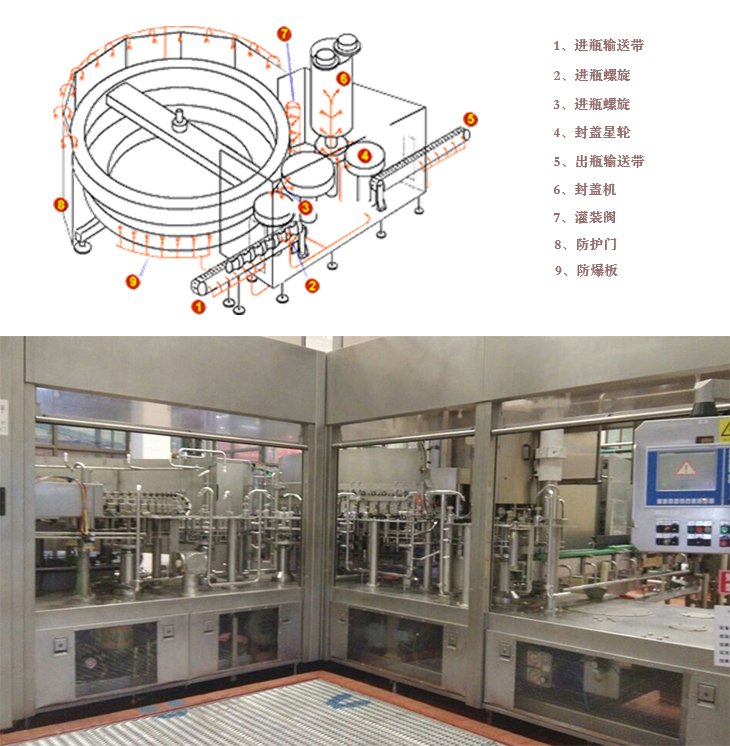

The system consists of the main station, from the station, pneumatic butterfly valve, fixed nozzle and related pipelines and other components. The main station can be achieved on the filling machine, capping machine and bottle washing machine exports to the sterilization machine entrance 20 meters of the conveyor chain for automatic cleaning, from the station can be manually manual to the various areas of cleaning.

Cleaning key points

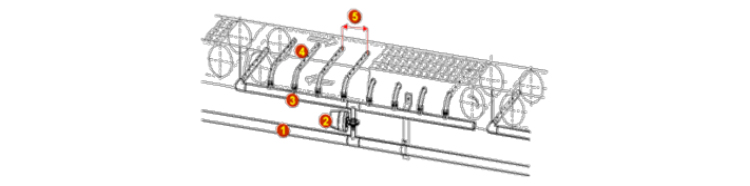

Conveyor belt cleaning

1) Cleaning main pipe 2) Partition valve 3) Cleaning branch pipe 4) Cleaning nozzle 5) Nozzle distance

Typical products

● EFC3000A Automatic Foam Cleaning System

● CF-2A automatic foam cleaning system

● ES-10 automatic foam cleaning system

Automatic cleaning system

Automatic cleaning system